功能测试

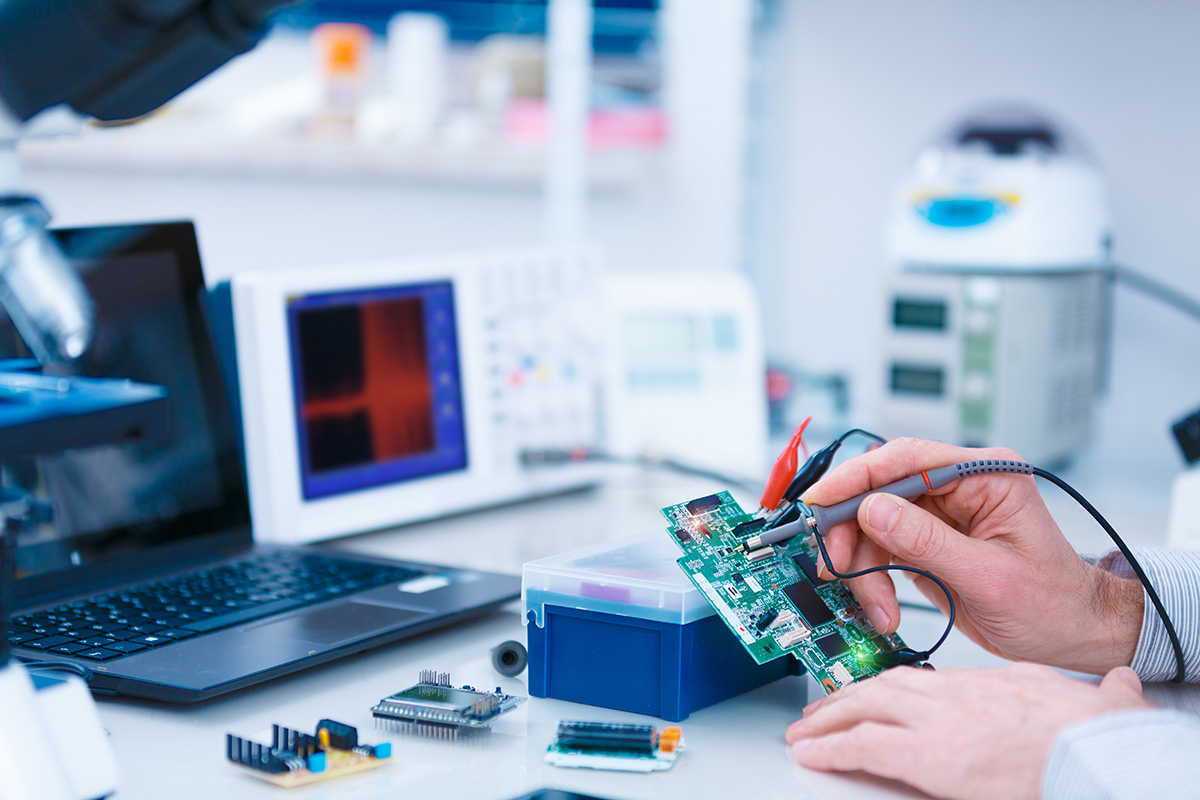

功能测试是 Bester 全面服务的一个重要方面。作为一家领先的 PCBA 制造商,我们深知确保每个电子元件和电路板功能完美无缺的重要性。功能测试是一个细致入微的过程,包括评估产品的性能和功能,验证其是否符合要求的规格和预期的性能。我们的技术熟练的技术人员和工程师团队使用先进的设备和技术,一丝不苟地进行一系列测试,以确定任何潜在的缺陷或问题。通过进行功能测试,我们确保客户获得最高质量和可靠性的产品,满足他们的特定要求和行业标准。

Bester 深知确保印刷电路板 (PCB) 功能性和可靠性的重要性。因此,我们提供一流的功能测试服务,以满足您的特定要求。我们经验丰富的技术人员和工程师团队采用先进的测试设备和方法,对印刷电路板的功能进行全面评估。从执行在线测试到功能测试,我们对每个元件和电路进行细致评估,以确定任何潜在的故障或问题。通过进行全面的功能测试,我们可以帮助您将缺陷风险降至最低,并确保您的印刷电路板具有最高水平的质量和性能。Bester 提供可靠、准确的功能测试服务,确保您的印刷电路板的功能性和可靠性,请相信我们。

其他信息

如何进行功能测试?

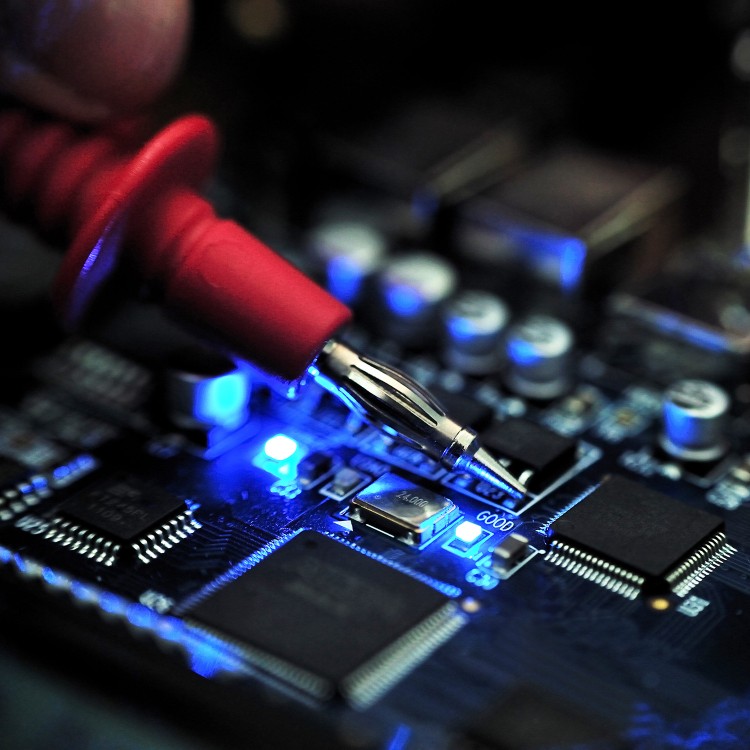

功能测试是 PCB 组装制造流程的最后一步。功能测试模拟操作环境,以确保 PCBA 的正确功能。操作环境可能包括与 PCBA DUT 通信的设备。通常,DUT 的电源和软件测试程序将加载必要的参数,使 DUT 正常工作。

功能测试将验证 PC 板组件的功能。其方法是根据为电路板开发的测试软件,应用一系列不同的信号和电流来刺激电路板的行为,然后测量 PCBA 的反应。它可以检测模拟和数字信号问题,包括失真、不正确的电流和信号时序问题。

印刷电路板组件 (PCBA) 可能会受到一系列信号和电源电压的影响。对特定点的响应进行监测,以确保功能正确。所有测试均按照客户测试工程师的规格和程序进行。

PCBA 功能测试夹具

目前已开发出许多不同的测试夹具,用于对 PCBA(印刷电路板组件)进行功能测试。电气连接可以使用 PCBA 上的连接器,也可以使用接触 PCB 设计人员定义的测试点的测试探针。测试夹具上的连接器通常经过改装,以方便夹具上的连接器与待测 PCBA 上的连接器配对和拆卸。连接器和待测 PCBA 上的连接器。测试夹具上的连接器通常也易于更换,因为在生产测试的多次插配和拆配过程中,连接器会很快磨损。

当与 PCBA 上的测试点直接接触时,PCBA 下面的探针通常是固定的,测试夹具对 PCBA 顶部施加压紧力,以便与测试探针进行可靠的电气连接。如果被测 PCBA 在电路板的两面都有测试点,则需要两个探针板,两个探针板必须相互精确对准,并与被测 PCBA 精确对准。采用双面探测时,被测 PCBA 通常固定在原位,当夹具操作时,探针从顶部和底部向内移动。

为什么选择 Bester

强大的装配能力

我们拥有最先进的设施和技术精湛的团队,有能力处理最复杂的 PCB 组装项目,确保高效、准确地制造您的产品。

质量保证

我们严格的质量控制流程和广泛的测试程序确保我们生产的每个 PCB 组件都符合可靠性和性能方面的最高行业标准,让您对我们的服务放心和充满信心。

一站式服务

从 PCB 制作和设计到元件采购和 IC 编程,Bester 在同一屋檐下为您提供全面的服务,简化生产流程,节省您的时间和精力。

快速周转

我们对快速周转时间的承诺意味着您的印刷电路板组装项目将如期完成,使您能够在截止日期前完成生产,并迅速将产品推向市场。

客户和认证

我们服务的行业

汽车

我们深知 PCBA 在汽车行业中的关键作用。我们提供全面的 PCBA 服务,满足汽车制造商的特定需求,帮助他们提供可靠、高性能的电子系统。

发光二极管

在 LED 市场,Bester 提供一流的 PCBA 解决方案,这对生产高质量的 LED 照明产品至关重要。我们与 LED 制造商密切合作,确保他们的 PCBA 符合能效、耐用性和性能方面的严格要求。

消费电子产品

Bester 通过提供广泛的 PCBA 服务来满足消费电子市场的需求,从而生产出创新的、用户友好的电子设备。我们与消费电子产品制造商合作,确保他们的 PCBA 符合最高的质量和功能标准。

工业

在工业领域,Bester 的 PCBA 服务在开发可靠、高效的电子系统方面发挥着至关重要的作用。我们与工业设备制造商密切合作,以满足他们的特定要求,确保我们的 PCBA 能够承受恶劣的环境条件,并提供最佳性能。

pcba 应用

自行车灯 PCBA

PIR 移动传感器 PCBA

LED PCBA

PCB 组装常见问题

您是经过认证的 PCB 制造商吗?

增材制造工艺又称快速成型制造工艺,是指利用加热打印头或激光等123444412312321 装置将各层材料结合在一起。这就是三维模型的精确复制品。

您是经过认证的 PCB 制造商吗?

增材制造工艺又称快速成型制造,是指使用三维打印机根据三维模型创建实体对象。该工艺需要逐层添加材料或长丝,然后使用粘合应用(如加热打印头或激光)将各层粘合在一起。最终得到的三维打印物体是原始三维模型的精确复制品。

您是经过认证的 PCB 制造商吗?

增材制造工艺又称添加式制造,是指使用三维打印机根据三维模型创建实体对象。该工艺需要逐层添加材料或长丝,然后使用熔融应用(如加热打印头或激光)将各层粘合在一起。最终得到的三维打印物体是原始三维模型的精确复制品。

你们提供快速 PCBA 服务吗?

快速成型材料工艺,也称为快速成型制造,是指使用三维打印机根据三维模型创建实体对象。该工艺需要逐层添加材料或长丝,然后使用熔融应用软件将材料熔化。

你们接受小批量订单吗?

增材制造工艺,又称增材制造,是指使用三维打印机根据三维模型创建实体对象。这一过程需要逐层添加材料或长丝,然后使用熔融应用(如加热打印头或激光)将各层粘合在一起。最终得到的三维打印物体是原始三维模型的精确复制品。