What is Environmental Stress Screening

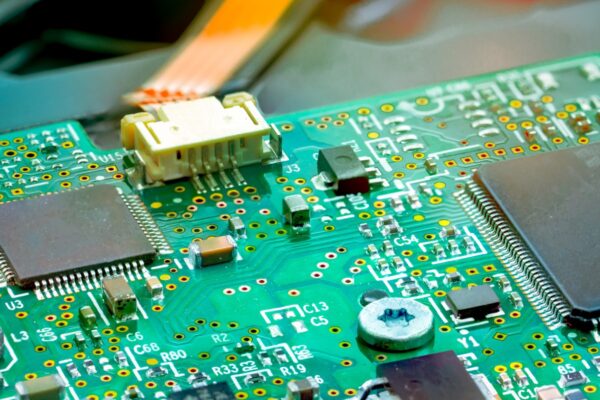

Environmental stress screening (ESS) is a crucial phase in the manufacturing process of electronic systems, particularly in the PCB industry. It involves subjecting electronic systems to a series of rigorous tests that simulate various environmental conditions, such as extreme temperatures, vibrations, dust, humidity, rain, and physical dropping. The primary objective of ESS is to identify any potential faults or weaknesses in the design of the electronic systems, ensuring that the final products are reliable and capable of functioning without any faults or failures in real-world operating conditions.

During ESS, the electronic systems undergo multiple tests that expose them to the specified environmental conditions. These tests are designed to push the systems to their limits and uncover any design flaws or weaknesses that may lead to failures or malfunctions in the field. If a product fails any of these tests, it indicates that there are flaws in its design, and the design team can then make the necessary corrections to improve its reliability and performance.

The implementation of ESS during the manufacturing process is crucial because it allows for the early detection of faults and weaknesses in the product. By identifying and rectifying these issues during the ESS phase, companies can save significant costs in the long run. Correcting design flaws during ESS prevents the need for costly product recalls and potential damage to the company’s reputation.