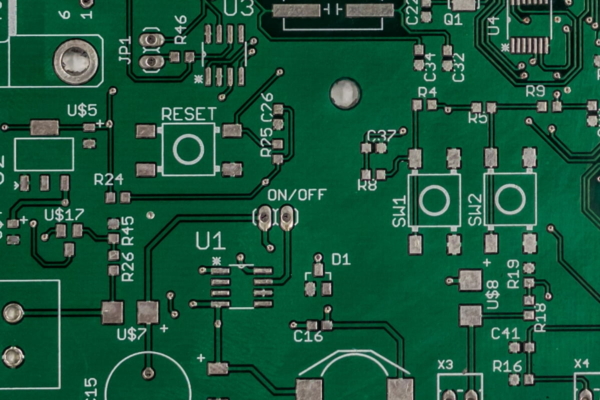

What is Electroless Nickel Immersion Gold (ENIG)

Electroless nickel immersion gold (ENIG) is a widely used double-layer metallic surface finish in the PCB industry. It involves the application of a thin layer of gold over a layer of nickel. The process begins by plating a nickel layer onto the copper pads of the PCB using an electroless process, which is a controlled chemical reaction. This is followed by the immersion of the nickel-plated PCB in a gold solution to deposit a layer of gold on top of the nickel layer.

ENIG provides excellent solderability, ensuring reliable solder joints during the assembly process. Secondly, it creates a flat and smooth surface, making it suitable for fine-pitch components and surface mount technology. Additionally, ENIG offers good corrosion resistance and is compatible with various bonding methods, including wire bonding and aluminum wire bonding.

The application of ENIG requires careful quality management to avoid issues such as “Black Pad.” Black Pad refers to a buildup of phosphorous between the gold and nickel layers, which can lead to fractured surfaces and faulty connections. To ensure the quality of ENIG boards, thorough testing and inspection are necessary at every stage of PCB fabrication and assembly.