What is Destructive Testing

Destructive testing is a systematic and detailed examination of a component during various stages of physical disassembly. This type of testing is conducted to ensure that the component meets the required standards and specifications, as well as to identify any design, workmanship, or processing problems that may not be detected through non-destructive testing methods.

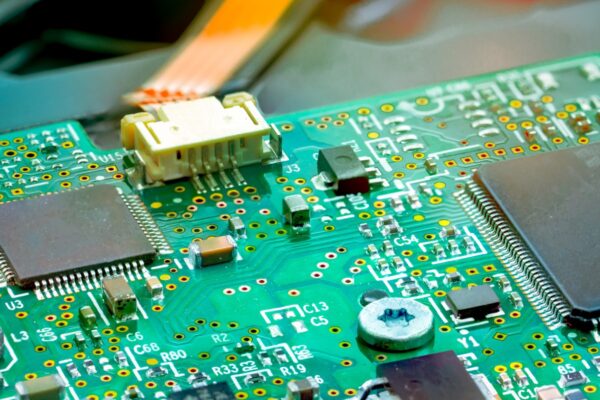

During destructive testing, the component is carefully disassembled, allowing for a thorough examination of its internal structure and components. Techniques such as delid/decap/case removal, internal visual inspection, bond pull strength testing, die shear testing, SEM inspection, and microsectioning are employed to assess the component’s construction and integrity.

The term destructive implies that the testing process may cause damage to the component being tested. However, this type of testing is necessary to uncover potential issues that may not be apparent through non-destructive testing methods. By performing destructive testing, manufacturers and quality control personnel can identify and address any design or manufacturing issues that could affect the performance or reliability of the component.