What is ATE

ATE, or Automated Test Equipment, is the systems or equipment that automate and streamline the testing process for electronic devices. These systems play a crucial role in ensuring the functionality and quality of electronic devices before they are integrated or delivered to end customers.

ATE systems are equipped with various test instruments and signal sources, including digital multimeters, LCR meters, oscilloscopes, signal generators, and arbitrary waveform generators. These instruments and sources are controlled and monitored by a high-performance data acquisition (DAQ) computer, often referred to as the master controller. The master controller runs specialized test software that controls and streamlines the instruments and signal sources in the test station.

The ATE system captures raw data from the test instruments and monitors, analyzes, and stores it using the master controller’s signal sources and test software. This data is then used to determine whether any changes need to be made to the device, whether it is ready for integration or delivery to end customers, or whether it is ready to be released for sale.

By automating the testing process, ATE systems help to improve efficiency, accuracy, and consistency in testing electronic devices. They eliminate human error and technical issues, allowing for faster and more reliable tests. ATE systems also enable a more efficient use of engineering resources, as engineers can focus on addressing occasional testing issues instead of performing tests manually.

Frequently Asked Questions

What Is Ate Boards

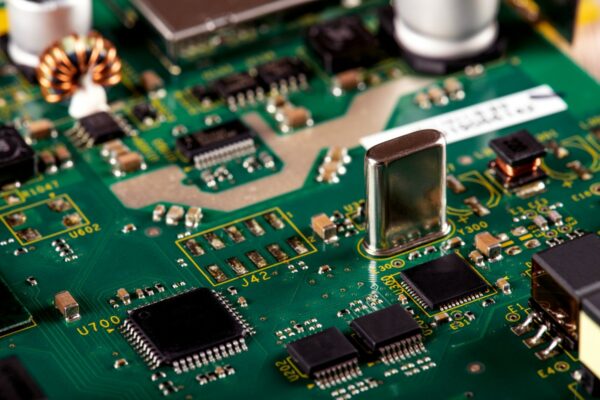

Automated Test Equipment (ATE) boards are utilized during the testing phase of semiconductor chips. These boards are specifically designed to cater to the requirements of high complexity, high performance, and high layer count in the testing process.

What Is the Full Form of Ate PCB Design

ATE PCB, which stands for Automated Testing Equipment Printed Circuit Board, is the solution for testing highly complex devices. As technology continues to advance, it becomes crucial to test these intricate devices to ensure their reliability.

What Is the Purpose of ATE

ATE is extensively utilized in the electronic manufacturing sector for the purpose of conducting tests on electronic components and systems once they have been manufactured. Additionally, ATE is employed in the testing of avionics and electronic modules found in automobiles. It also finds applications in military sectors such as radar and wireless communication.

What Are the Advantages of ATE

Basic ATE components offer several advantages. These include automatic measurements that enhance testing speed, improved accuracy by eliminating human involvement, and cost reduction for high repetition rates of DUT’s. It is worth noting that while the disadvantages of ATE are few, they are still significant.