Protoboards and breadboards are essential for prototyping, but they have some key differences. This article explains those differences, covering their pros, cons, and best uses to help you choose the right tool for your project.

What Are Protoboards and Breadboards

To fully appreciate the differences between protoboards and breadboards, we must first understand what each of these tools is and how they function in electronics prototyping.

Protoboards, also known as prototype boards, are fundamental to circuit design. These boards are specifically designed for creating permanent electronic circuits, a step beyond the temporary designs often created on breadboards. A protoboard’s primary appeal lies in its permanence. Unlike breadboards, protoboards are all about creating lasting circuits. Soldering components directly onto the board ensures a stable and enduring connection, ideal for finalized projects or prototypes requiring a more robust and long-lasting solution.

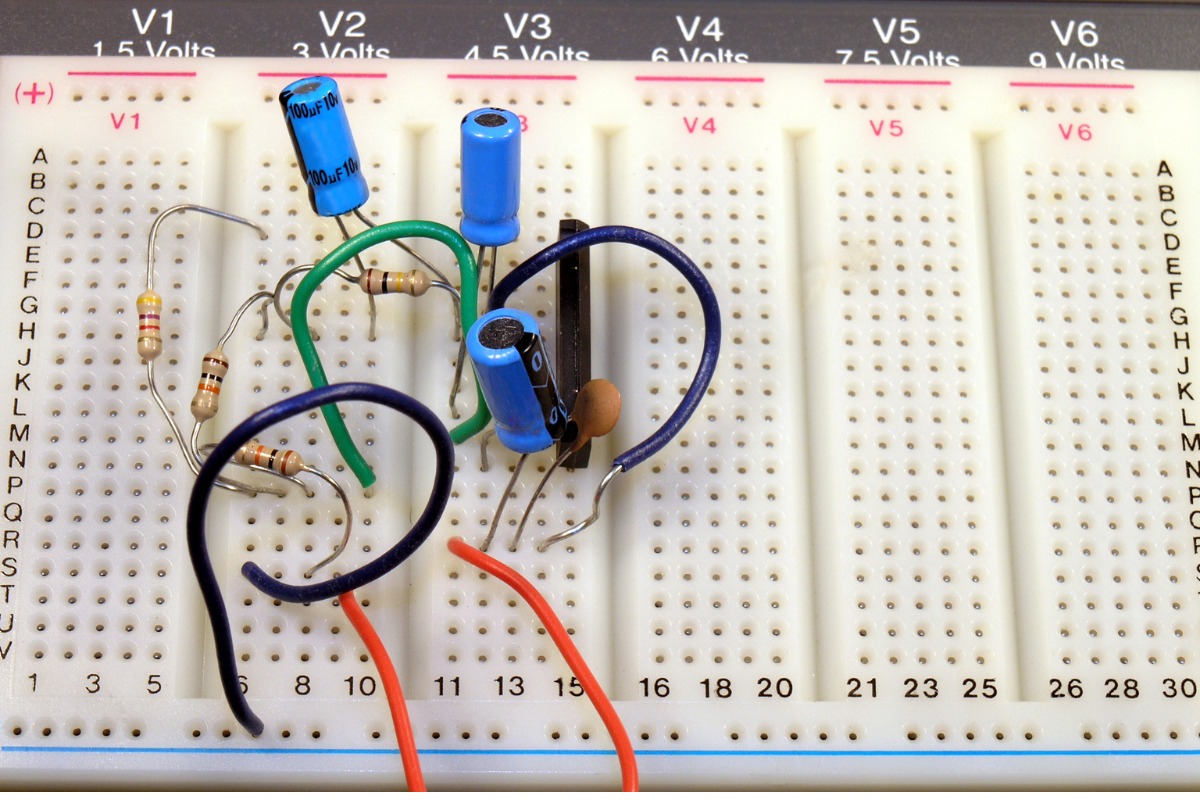

Breadboards, conversely, serve as solderless bases for prototyping electronic circuits. These versatile platforms are designed for creating temporary prototypes, allowing quick assembly and modification of circuits without soldering. Breadboards have gained immense popularity among students, hobbyists, and even professional engineers due to their ease of use and reusability.

A breadboard’s clever structure is essential to how it works. A modern solderless breadboard consists of a perforated block of plastic with numerous tin-plated phosphor bronze or nickel silver alloy spring clips underneath. These clips, often called tie points or contact points, are central to the breadboard’s versatility. The number of tie points is frequently specified in the breadboard’s description, indicating its capacity.

Lead pitch – the spacing between clips – is critical to a breadboard’s design. This spacing is typically 0.1 inches (2.54 mm), a standard measurement in electronics. This specific spacing accommodates ICs in DIPs, which can straddle the centerline. The remaining holes accommodate interconnecting wires and the leads of discrete components like capacitors, resistors, and inductors, enabling complex circuit completion.

The primary distinctions between protoboards and breadboards lie in their connection methods and primary uses. Protoboard connections are highly stable due to soldering. Soldered components tend to stay put and withstand mechanical stress better than components on a breadboard. This stability makes protoboards ideal for more permanent circuit designs and projects that require higher durability.

Breadboards, on the other hand, allow easy component insertion and removal without soldering. This makes them perfect for quick prototyping and experimentation. The ability to rapidly assemble, test, and modify circuits without soldering makes breadboards invaluable for iterative design and educational settings.

Fundamentally, while both serve the purpose of circuit prototyping, they cater to different design stages and project requirements. Protoboards are best suited for creating more permanent, robust circuit designs, while breadboards excel in rapid prototyping, experimentation, and temporary circuit assemblies.

Design and Structure Comparison

To fully appreciate the strengths and limitations of each, delving deeper into their design and structural characteristics is crucial. Let’s examine each thoroughly and then compare their important structural aspects.

Breadboard Structure

The internal structure of a breadboard is a marvel of simplicity and functionality. The board is typically divided into three main sections: the center part and two power rail sections on the sides.

The center part is the heart of the prototyping area. It’s divided into two rows, each with multiple vertical columns. Each column typically contains five interconnected pins. This arrangement is crucial. When a component’s lead or a wire is inserted into one of these holes, it contacts the metal clip below, connected to the other four holes in that column. This design allows easy connections without soldering.

At the top and bottom, you’ll find horizontally connected rows designed for power supply connections. Typically, one row is used for the positive voltage supply and the other for ground. These power rails run the length of the breadboard, simplifying power distribution.

The standard 2.54 mm spacing (0.1 inches) between clips, or lead pitch, is a critical aspect of the breadboard’s design. This standardized spacing accommodates the pins of most standard electronic components, particularly ICs. The center channel is typically wide enough to allow DIPs to straddle it, with their pins inserting into the rows on either side.

Protoboard Structure

Protoboards, while serving a similar purpose, have a distinctly different structure. A protoboard is essentially a PCB with a specific layout designed to emulate breadboard connections. Unlike breadboards, however, protoboards require soldering to secure components and create connections.

The surface typically consists of copper pads arranged in a grid pattern. These pads are often connected similarly to a breadboard, with rows of connected pads for component placement. Many protoboards also include common “bus” strips on each side, mimicking breadboard power rails.

Protoboards feature holes in each copper pad. These holes allow component leads and wires to be inserted and then soldered. This design combines the familiar layout of a breadboard with the permanence and stability of soldered connections.

Some may also include additional features such as mounting holes for securing the board in an enclosure, or larger pads for connecting power supplies or other external components.

Structural Comparison

Comparing protoboard and breadboard structures reveals several important differences:

The most obvious difference lies in how connections are made. Breadboards use temporary, solderless connections via spring clips, allowing easy insertion and removal of components. Protoboards require permanent, soldered connections. This fundamental difference greatly impacts their use cases and flexibility.

Breadboards offer greater flexibility in circuit layout. Components can be easily rearranged, and connections modified quickly. With protoboards, modifying the circuit layout after soldering becomes much more challenging and time-consuming.

Protoboards’ soldered connections generally offer greater durability and reliability compared to breadboards’ friction-based connections. This makes them more suitable for projects that must withstand physical stress or vibration.

While both can accommodate a wide range of components, breadboards typically offer more tie points in a compact space. Protoboards, however, can be custom-designed for specific project needs, potentially offering greater capacity for complex circuits.

Both usually include dedicated power distribution areas. In breadboards, these are the horizontal power rails; in protoboards, they’re often larger copper areas or bus strips.

Due to their soldered connections and potential for shorter signal paths, protoboards can offer better signal integrity, especially for high-frequency circuits. Breadboards, with their higher parasitic capacitance and inductance, may introduce more noise and signal degradation in sensitive circuits.

Pros and Cons of Protoboards and Breadboards

So, both protoboards and breadboards have their pros and cons. Understanding these can help you make an informed decision about which tool best suits your project needs. Let’s explore the advantages and disadvantages of each thoroughly.

Protoboard Advantages

Stable and Robust Connections

An exceptionally secure and durable link between components is achieved with soldered joints, which can withstand mechanical stress and vibration better than breadboard connections. This stability is particularly valuable in projects requiring long-term reliability or subject to physical movement or harsh environments.

Ideal for Fixed Circuit Configurations

Protoboards excel when implementing a finalized circuit design in a more permanent form. Transferring a perfected breadboard circuit to a protoboard creates a more robust and long-lasting prototype. This makes protoboards particularly useful for projects nearing the final product stage or for creating durable prototypes for field testing.

Custom Circuit Layouts

Protoboards offer the flexibility of custom circuit layouts. Unlike breadboards with their fixed patterns, protoboards allow you to design your own connection paths. This customization can lead to more efficient space usage and potentially better circuit performance, especially for complex designs.

Suitable for Complex Circuits

The permanent soldered connections and custom layouts make protoboards well-suited for more complex circuit designs. You can create intricate connection patterns and multi-layer designs that might be challenging or impossible on a breadboard. This is particularly valuable for advanced projects or when working with high-frequency circuits requiring careful signal routing.

Better Signal Integrity

Soldered connections typically offer lower resistance and inductance compared to breadboard spring clip connections. This results in better signal integrity, crucial for sensitive analog circuits or high-speed digital designs. Creating shorter, more direct connections on a protoboard can reduce noise and interference.

Protoboard Disadvantages

Require Soldering Skills

The need for soldering skills can be a significant obstacle to using protoboards. Soldering requires practice and involves high-temperature tools, which can be intimidating for beginners. The quality of soldered connections greatly affects circuit performance and reliability, so expertise is necessary for good results.

Less Suitable for Rapid Prototyping

While soldered connections provide stability, they make protoboards less ideal for rapid prototyping where frequent modifications are necessary. Modifying a soldered circuit becomes time-consuming and challenging, which can slow down the iterative design process, especially in the early stages.

Time-Consuming Modifications

Modifying a soldered circuit often involves desoldering components, a tedious and time-consuming process. This can be particularly frustrating when working on a complex circuit requiring multiple changes. The risk of component or board damage during desoldering is also a concern.

Limited Reusability

Unlike breadboards, which are easily cleared and reused, protoboards are generally committed to a single circuit design once soldered. While it’s possible to desolder everything and start over, this is time-consuming and may damage the board, making them less cost-effective for multiple short-term projects.

Potential for Heat Damage

The soldering process involves applying heat. If not done carefully, this could damage sensitive components or the board. This risk is particularly relevant when working with heat-sensitive components or making multiple modifications to the same area.

Breadboard Advantages

No Soldering Required

New to electronics? Breadboards are an excellent starting point. They require no soldering, making them accessible to beginners and ideal for education where students can quickly assemble and disassemble circuits without specialized tools or skills. The solderless design also eliminates the risk of heat damage during assembly.

Perfect for Quick Prototyping and Experimentation

Breadboards excel when rapid prototyping and experimentation are necessary. You can quickly insert components, test different configurations, and make changes on the fly. This flexibility is invaluable during initial circuit design when exploring different ideas and needing to iterate quickly.

Ideal for Beginners and Educational Purposes

Though convenient, the friction-based connections in breadboards can become loose…The ease of use and non-permanent nature make them excellent for those new to electronics. They provide a low-risk environment for learning about circuit design, component behavior, and basic electronics principles. In classrooms, breadboards allow students to build and modify circuits quickly, reinforcing theoretical concepts with hands-on experience.

Highly Reusable

Breadboards can be used repeatedly for different projects. After using a breadboard circuit, you can easily remove the components and start fresh. This reusability makes them cost-effective for hobbyists, students, and professionals working on multiple short-term projects or frequently testing different circuit ideas.

Visual Representation of Circuit Layout

The grid-like structure provides a clear visual representation of the circuit layout. This helps understand circuit flow and troubleshooting, as connections can be easily traced and potential issues identified.

Breadboard Disadvantages

Connections Can Become Loose Over Time

Though convenient, the friction-based connections in breadboards can become loose with repeated use or when subjected to vibration. This can lead to intermittent connections or circuit failures, which can be frustrating and difficult to diagnose. In projects requiring long-term reliability, this can be a significant drawback.

Best Suited for Simpler Circuits

While breadboards can accommodate a wide range of circuits, they might prove challenging for highly complex designs. As circuit complexity increases, the limitations of the fixed connection pattern and the potential for signal interference between closely spaced components can become more problematic.

High Parasitic Capacitance

Breadboards have relatively high parasitic capacitance compared to properly designed PCBs. This can affect circuit performance, especially in high-frequency applications, causing signal distortion, timing issues in digital circuits, or unwanted oscillations in analog designs.

Limited to Operation at Relatively Low Frequencies

Due to the parasitic capacitance and the relatively long, unshielded connections, breadboards are generally limited to operation below 10 MHz. This makes them less suitable for high-speed digital circuits or RF applications.

Cannot Accommodate SMT Devices

Breadboards are designed for through-hole components and cannot directly accommodate SMT devices, which are increasingly common in modern electronics. While adapters exist for some SMT packages, this limits the component types usable in prototypes.

Parasitic Resistance, Inductance, and Capacitance

The internal structure introduces parasitic elements that can affect performance. These include resistance in the contact points, inductance in the long connection paths, and capacitance between adjacent rows. In sensitive analog circuits or high-speed digital designs, these parasitic elements can lead to unexpected behavior or degraded performance.

When to Use Protoboards vs Breadboards

Choosing between a protoboard and a breadboard is a critical decision for your project. Which is right for your project? Each tool has its strengths and is suited to different design stages and project types. Let’s explore the specific use cases for each and the factors to consider when making your choice.

Protoboard Use Cases

Protoboards are ideal in several situations:

Permanent Projects Requiring Stable Connections

If your project is intended for long-term use or production, protoboards are suitable. They provide stable connections and a more durable solution, ideal for projects needing to withstand regular use or environmental stresses. For instance, a device used in a vibration-prone environment would benefit from a protoboard’s soldered connections.

Complex Circuits That Need Custom Layouts

Protoboards excel in handling complex circuits requiring precision and custom layouts. Engineers often use them when building prototypes for more advanced electronic devices. Creating custom trace patterns and multi-layer designs allows for more efficient space usage and potentially better circuit performance. This is particularly useful for high-frequency circuits or designs requiring careful signal routing to minimize interference.

Projects Where Soldering Skills Are Available

If you’re comfortable with soldering and have the necessary equipment, protoboards offer a valuable platform. Creating solid, permanent connections leads to more reliable and professional-looking prototypes. This is especially important for proof-of-concept presentations where appearance and durability are as important as functionality.

Creating a More Finalized Prototype Before PCB Production

Protoboards are an excellent intermediate step between breadboard prototypes and final PCB designs. They allow you to create a more permanent and refined circuit version, useful for extended testing or as a pre-production model. This step can help identify any issues not apparent in the breadboard stage, potentially saving time and resources in the final PCB design process.

Breadboard Use Cases

Breadboards are preferable in these situations:

Prototyping and Validating Circuit Designs Quickly

Breadboards provide a remarkably quick and flexible way to test and validate circuit designs before committing to a permanent solution. If you’re in the early stages of a project and need to experiment with different component values or circuit configurations, a breadboard allows you to make these changes rapidly without soldering or desoldering.

Educational Purposes, Teaching Students About Circuit Design

If you’re learning about circuits, breadboards are a great tool. Their ease of use and non-permanent nature make them ideal for classroom settings, allowing students to build, test, and modify circuits without specialized tools or the risk of damaging components through soldering.

Temporary Circuits for Specific Projects or Experiments

If you need a temporary circuit, a breadboard allows easy assembly and disassembly. This is particularly useful for short-term projects or when you need to set up a circuit quickly for testing or demonstration purposes.

Rapid Prototyping and Idea Testing

For quick experimentation, idea testing, and proof of concept, breadboards are unbeatable. They allow you to assemble and modify circuits on the fly, saving time and effort in the early stages of design. This rapid prototyping capability is invaluable when exploring multiple design options or troubleshooting complex systems.

Beginners Learning Electronics

If you’re new to electronics or want to introduce someone to circuit building, breadboards are an excellent starting point. They offer a gentle learning curve and require no soldering skills, allowing beginners to focus on understanding circuit principles

Considerations for Specific Circuit Types

When deciding, consider the specific circuit type:

- Digital Circuits: While usable for many digital circuits, breadboards can present challenges for high-speed designs. The extremely fast edge speeds, even at relatively low clock rates, can produce high-frequency effects causing issues. Without controlled impedances, these fast edges can result in ringing and false triggering. Protoboards may be more suitable for creating stable digital circuit prototypes in such cases.

- Analog Circuits: For low-frequency analog circuits, breadboards can be quite effective. However, for precision analog circuits or those operating at higher frequencies, the parasitic elements (resistance, capacitance, and inductance) can significantly affect performance. A carefully designed protoboard layout may yield better results in these cases.

- Mixed-Signal Circuits: With circuits combining analog and digital elements, the choice becomes more complex. You may need to consider using a combination of both, or opt for a protoboard with a carefully planned layout to minimize interference between analog and digital sections.

Factors to Consider When Choosing

When deciding, consider these factors:

- Circuit Complexity: For simple circuits, breadboards are often the quickest and easiest option. As complexity increases, the benefits of protoboards – custom layouts and more stable connections – become more significant.

- Permanence vs. Flexibility: If your project requires a more permanent solution or will be subject to physical stress, a protoboard is likely better. If you need flexibility for frequent changes or are still experimenting, a breadboard would be more appropriate.

- Skill Level and Available Tools: Your comfort level with soldering and the tools you have available should influence your decision. If you’re new to electronics or lack soldering equipment, breadboards are more accessible.

- Project Timeline and Need for Iterations: Consider your project timeline and the number of design iterations you expect. Breadboards allow faster changes but may not be suitable for long-term use, while protoboards take more time to set up initially but provide a more stable long-term solution.

- Signal Integrity Requirements: If your circuit is sensitive to noise or operates at high frequencies, the superior signal integrity of a well-designed protoboard layout may be necessary.

- Budget and Reusability: Breadboards are generally less expensive and reusable for multiple projects, making them more cost-effective for hobbyists or those working on multiple short-term projects.

Often, the most effective approach is using both at different project stages. You might start with a breadboard for initial prototyping and experimentation, then move to a protoboard for a more refined and stable version before finalizing the design on a custom PCB.