PCB Desgin

PCB design is the process of creating the layout and arrangement of electronic components on a PCB. This crucial step in the manufacturing process involves translating the schematic diagram of a circuit into a physical design that can be manufactured and assembled. Our team of skilled and experienced designers utilizes the latest design software and tools to ensure accurate and efficient PCB designs. With a keen attention to detail and a focus on functionality, we aim to create PCB designs that are optimized for performance, reliability, and manufacturability. Whether you require a simple single-layer design or a complex multilayer design, we have the expertise to deliver high-quality PCB designs that meet your specific requirements.

At Bester, we take pride in delivering top-notch PCB Design services to our valued customers. With a team of highly skilled and experienced designers, we ensure that each project is meticulously crafted to meet the unique requirements and specifications of our clients. Our cutting-edge design software and advanced technology enable us to create highly efficient and innovative PCB designs that are optimized for performance, reliability, and cost-effectiveness. We work closely with our customers throughout the design process, providing constant communication and feedback to ensure their expectations are exceeded. Whether it’s a complex multi-layer design or a simple single-layer board, we have the expertise and resources to deliver exceptional PCB Design solutions that meet the highest industry standards. Trust Bester for all your PCB Design needs and experience the difference of quality and excellence.

PCB DESIGN SERVICE CAPABILITIES

Schematic Capture

We can create schematics from specifications, marked-up schematic sheets, or black diagrams and verbal discussions. We accept schematics in any format (PDF, sketch, etc.) and can convert that into preferred CAD format. As part of our process we validate the BOM.

Reverse Engineering

We can take an existing board from a bare board, an assembled board, existing design files and drawings. And we can create a new design with all supporting documentation.

Cost Optimization

We can review an existing product or design and propose methods for cost reduction. In many cases, layer reduction can be achieved by using smaller geometries for conductors and vias and the use of laser-drilled microvias.

PCB Stack-Up Design

Before we start the layout design, we will do an in-house stackup design so that all the design objectives are met. We will also suggest if HDI technology is required or could help in PCB optimization.

PCB Design Tools

We use the standard tools from Cadence, Mentor Graphics and Altium. We can accept a netlist or a partial / fully placed netlist. We can use our library of parts or customer libraries. We can provide. A 24/7 service and our design team can schedule video conferences to support you. We have access to off-shore resources that can work on your design while you sleep.

Signal Integrity Services

We can perform signal integrity services on any high-speed board designs that we make. We will take care of control impedance and crosstalk requirements; we will take care of PCB materials that are suitable to achieve a given set of signal integrity specifications.

Why Choose Bester

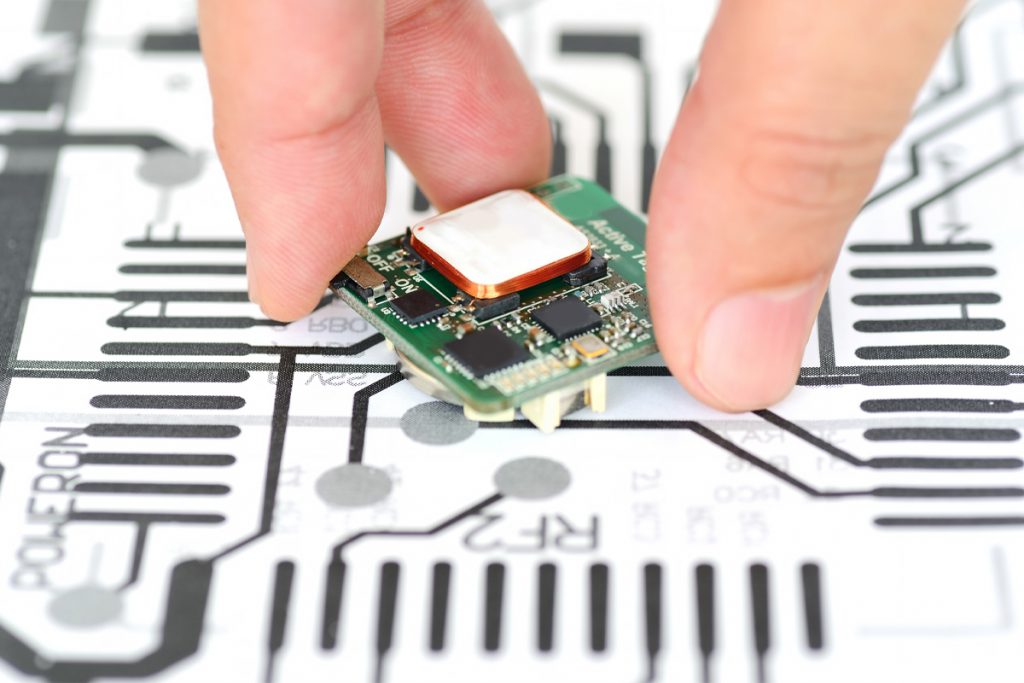

Strong Assembly Capacities

With state-of-the-art facilities and a highly skilled team, we have the capacity to handle even the most complex PCB assembly projects, ensuring your products are manufactured efficiently and accurately.

Quality Assurance

Our rigorous quality control processes and extensive testing procedures guarantee that every PCB assembly we produce meets the highest industry standards for reliability and performance, giving you peace of mind and confidence in our services.

One-stop Service

From PCB fabrication and design to component sourcing and IC programming, Bester offers a comprehensive range of services under one roof, streamlining the production process and saving you time and effort.

Fast Turnaround

Our commitment to fast turnaround times means that your PCB assembly projects will be completed on schedule, allowing you to meet your production deadlines and get your products to market quickly.

Clients and Certifications

Industries We Serve

Automotive

We understand the critical role that PCBA plays in the automotive industry. With our comprehensive PCBA services, we cater to the specific needs of automotive manufacturers, helping them deliver reliable and high-performing electronic systems.

LED

In the LED market, Bester provides top-notch PCBA solutions that are essential for the production of high-quality LED lighting products. We work closely with LED manufacturers to ensure that their PCBAs meet the stringent requirements of energy efficiency, durability, and performance.

Consumer Electronics

Bester caters to the consumer electronics market by offering a wide range of PCBA services that enable the production of innovative and user-friendly electronic devices. We collaborate with consumer electronics manufacturers to ensure that their PCBAs meet the highest standards of quality and functionality.

Industrial

In the industrial sector, Bester’s PCBA services play a crucial role in the development of reliable and efficient electronic systems. We work closely with industrial equipment manufacturers to meet their specific requirements, ensuring that our PCBAs can withstand harsh environmental conditions and deliver optimal performance.

PCBA APPLICATIONS

Bike Light PCBA

PIR Motion Sensor PCBA

LED PCBA

PCB Assembly FAQs

Are you a certified PCB manufacturer?

Additive material process, also known as additive manufacturing, involves the123444412312312321on, such as a heated printhead or laser, to bind the layers together. Th an exact replica of the original 3D mg a fusing applicag a fusing applicaodel.

Are you a certified PCB manufacturer?

Additive material process, also known as additive manufacturing, involves the use of 3D printers to create a solid object from a 3D model. The process entails adding the material or filament layer by layer, and then using a fusing application, sug a fusing applicag a fusing applicag a fusing applicag a fusing applicag a fusing applicach as a heated printhead or laser, to bind the layers together. The end result is a 3D-printed object that is an exact replica of the original 3D model.

Are you a certified PCB manufacturer?

Additive material process, also known as additive manufacturing, involves the use of 3D printers to create a solid object from a 3D model. The process entails adding the material or filament layer by layer, and then using a fusing application, such as a heated printhead or laser, to bind the layers together. The end result is a 3D-printed object that is an exact replica of the original 3D model.

Do you offer quick turn PCBA service?

Additive material process, also known as additive manufacturing, involves the use of 3D printers to create a solid object from a 3D model. The process entails adding the material or filament layer by layer, and then using a fusing applicati

Do you accept small-batch orders?

Additive material process, also known as additive manufacturing, invg a fusing applicag a fusing applicag a fusing applicag a fusing applicag a fusing applicag a fusing applicag a fusing applicag a fusing applicaolves the use of 3D printers to create a solid object from a 3D model. The process entails adding the material or filament layer by layer, and then using a fusing application, such as a heated printhead or laser, to bind the layers together. The end result is a 3D-printed object that is an exact replica of the original 3D model.