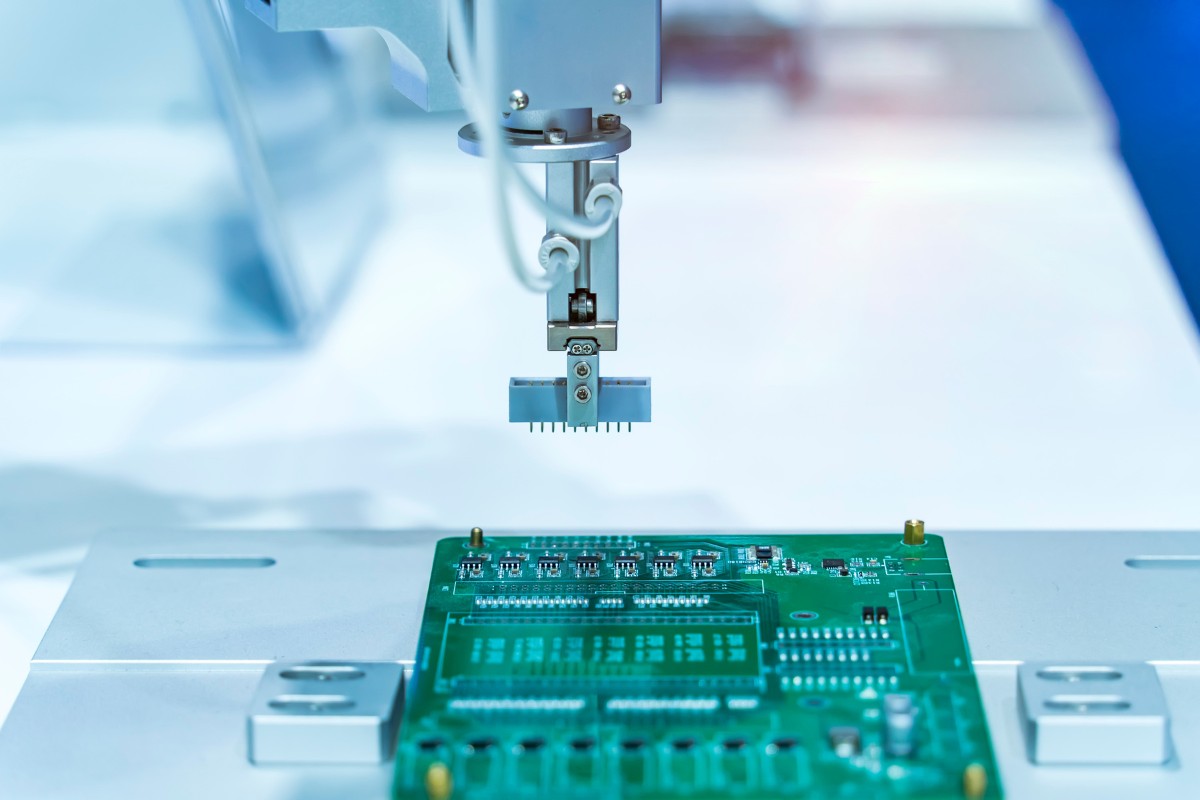

It often does not make sense to invest in expensive production equipment if you merely wish to spin a small number of prototypes and instead outsource your PCB assembly and prototype manufacturing to a trustworthy vendor. I will demonstrate what to look out for when selecting a vendor and provide some pointers on which services modern suppliers offer.

Using Online Quotation Systems

Some vendors will feature an instant online quotation system on their website, which will save time when choosing a supplier. This quote system should enable you to enter all the board details, including board thickness, material, and any special manufacturing requirements like milling. Early verification of these parameters helps to avoid unexpected costs and delays associated with special requirements.

Understanding Cost Implications

The per-board cost typically decreases as the quantity increases due to the amortized setup expense. Many manufacturers implement a system where they combine boards from multiple customers. By doing this, the setup cost is distributed among several clients, making it more cost-effective for each. During the design phase, consider starting with a smaller quantity to identify and rectify design issues before scaling up production, which can significantly optimize your budget.

Material and Design Limitations

One limitation with small-quantity prototypes is that the variety of materials and material thicknesses will be limited. If you are using a special material, chances are there won’t be other customers utilizing the same material, which might increase costs or lead times. In such cases, engaging early with suppliers about material availability can circumvent potential obstacles.

Compatibility and Modifications

Ensure that you can provide the file formats that your vendor needs. The most widely accepted format is the Gerber format for PCB production. Some companies are also capable of reading design software-specific file formats, offering a broader range of compatibility. Many suppliers offer in-house PCB design services; even if you design your board yourself, choosing a supplier with design services may prove invaluable in case there are issues with your files, allowing for quick modifications that can prevent costly delays.

Handling Special Component Types

When outsourcing PCB assembly, ensure that your vendor can mount all of the package types that your board uses. Some manufacturers may not be able to assemble certain types of IC packages, such as BGAs, chip-scale packages, or very small component types. If in doubt, make sure to email your supplier in advance to confirm capability.

Leveraging Vendor Inventory

If you aim to simplify the ordering process of board components, you might choose a vendor that stocks standard components. This means you only need to consign special types of components. When utilizing your vendor’s inventory, clearly indicate which parts you are consigning in your bill of materials. The BOM you upload to your vendor’s website must include this critical information.

Purchasing SMT Stencils and Ensuring Testing

Most manufacturers also offer the manufacture of the SMT stencil required for PCB assembly. Be sure to purchase the stencil along with the circuit boards themselves to eliminate delays. Regarding testing, ensure that your supplier supports the board test methods you need. Some tests might necessitate building specific test equipment, which will require additional time and cost. Also, confirm that your vendor maintains suitable quality management approvals.

Navigating Compliance

It’s vital to understand the impacts of various regulations or industry standards on your projects. Engaging with vendors who adhere strictly to industry standards, such as ISO certifications, can enhance product reliability and market acceptance.

Staying Ahead

Insight into upcoming changes or innovations in PCB assembly can prepare you for future shifts in the industry. Technologies such as flexible PCBs, miniaturized components, and advanced material sciences are shaping the future. Engaging in discussions with your supplier about these trends will keep your products competitive and technologically relevant.

By following these detailed guidelines and considerations, businesses can make informed decisions when outsourcing PCB assembly and prototype production, ensuring quality, efficiency, and cost-effectiveness in their projects.