Blank PCBs are essential. They are the foundation of modern electronics. These bare boards are the starting point for the intricate circuits found in every electronic device. This guide explores the types, manufacturing processes, and applications of blank PCBs, offering insight into their vital role in electronics manufacturing.

What is a Blank PCB

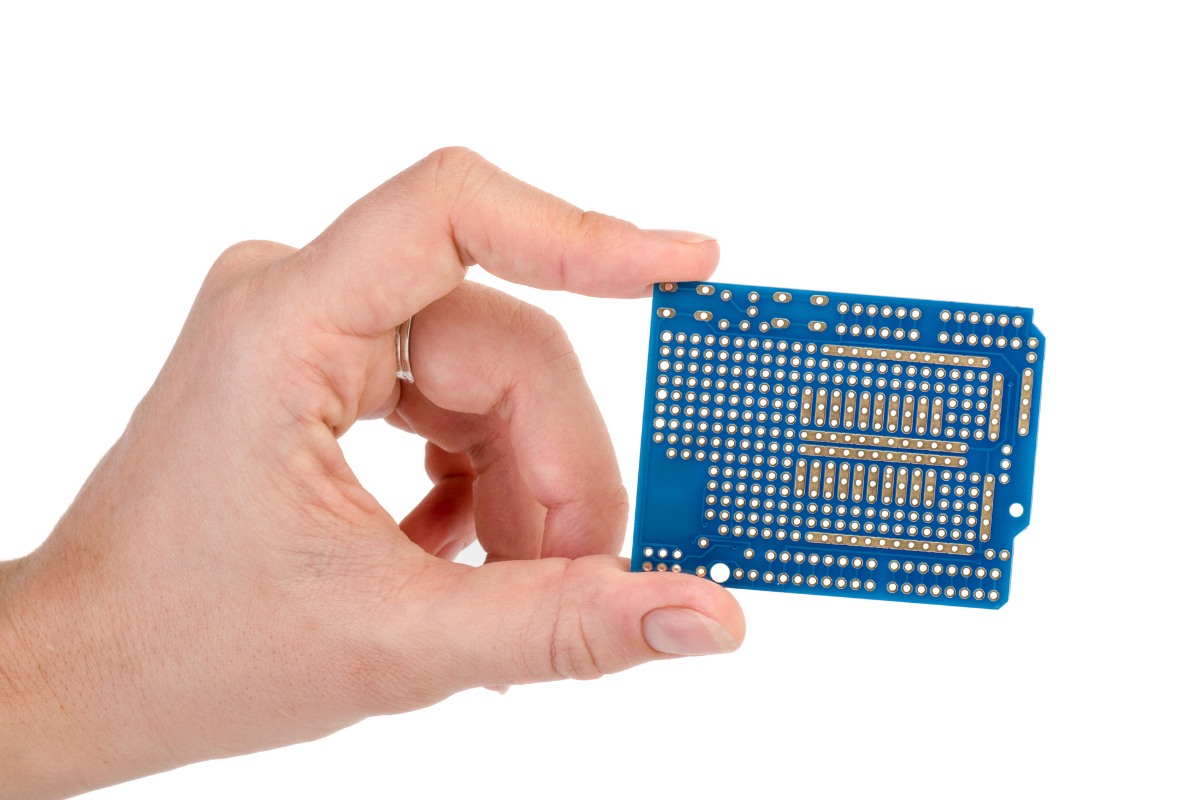

A blank PCB, also known as a bare or empty PCB, is the foundational element of electronic circuit boards. It’s an electronic board without components or etched circuits—a clean slate for creating functional electronic devices. But what exactly makes up these seemingly simple boards?

At its core, a blank PCB consists of several components. The base is typically epoxy glass fiber, providing structural integrity and insulation. This substrate is laminated with copper foil, creating the conductive layer for future circuit paths. This copper coating is why blank PCBs are sometimes called “copper clad” circuit boards.

The layered structure of a blank PCB is essential to its functionality. It consists of alternating layers of conductive copper and non-conductive substrate materials. This structure allows for complex circuit designs, especially in multilayer PCBs accommodating more intricate electronic systems.

Why start with a blank board? Because it offers unparalleled versatility and customization. They provide a standardized foundation for engineers and designers to create a wide array of electronic circuits. Starting with a blank slate, manufacturers can tailor the PCB to specific requirements, whether for a simple household appliance or sophisticated medical equipment.

Blank PCBs also ensure the efficient flow of electrical current within a device. The copper layers, when properly etched and designed, direct electricity precisely where needed, minimizing signal interference or overheating. This careful current control is essential for proper function and device longevity.

Types of Blank PCBs

Blank PCBs offer a surprising variety, each designed to meet different electronic needs. We’ll now examine the main categories and their specific attributes.

FR-4 PCBs

FR-4 PCBs are widely considered the workhorses of the electronics industry. FR-4 (Flame Retardant-4) refers to the material’s composition and properties. These PCBs are made from epoxy resin reinforced with woven fiberglass, creating a robust and reliable substrate.

The popularity of FR-4 PCBs stems from their excellent balance of electrical, mechanical, and thermal properties. They offer good electrical insulation, mechanical strength, and moisture resistance. The cost-effectiveness and ease of fabrication of FR-4 PCBs make them the preferred option for a wide range of electronic applications, from consumer electronics to industrial equipment.

Metal Core PCBs

Metal core PCBs excel at managing heat in electronic devices. These PCBs have a metal base, typically aluminum or copper, forming the board’s core.

Metal core PCBs offer the advantage of high thermal conductivity. This makes them exceptionally effective at dissipating heat, crucial for high-power applications. You’ll likely find metal core PCBs in LED lighting systems, power supplies, and automotive electronics, where efficient heat management is paramount for performance and longevity.

Flexible and Rigid-Flex PCBs

As electronic devices become increasingly compact and versatile, flexible and rigid-flex PCBs are rising in importance. Flexible PCBs are made from materials like polyimide (PI) or PET, allowing the board to bend and flex without breaking. This flexibility opens up new possibilities in product design, especially for devices in tight or irregularly shaped spaces.

Unlike flexible PCBs, which bend and flex, rigid-flex PCBs combine both flexible and rigid sections. This hybrid design allows for complex three-dimensional configurations, making them ideal for space-constrained applications like wearable technology, smartphones, and medical devices.

High-Frequency PCBs

With increasing demand, high-frequency PCBs are designed to handle signals in the radio frequency (RF) and microwave ranges. They’re typically made from materials like PTFE, offering low dielectric loss and consistent electrical properties at high frequencies.

These specialized PCBs are essential for applications requiring rapid and precise signal transmission. They’re used in telecommunications equipment, radar systems, satellite communications, and even 5G smartphones. Their ability to maintain signal integrity at high frequencies is indispensable in our increasingly wireless world.

Ceramic PCBs

In extreme environments, ceramic PCBs are particularly useful. Made from materials like aluminum nitride (AlN) or alumina, they offer unparalleled thermal conductivity and stability. They withstand high temperatures and harsh conditions that would cause other PCB types to fail.

These robust PCBs are essential for specialized applications demanding reliability under extreme conditions. You’ll find ceramic PCBs in high-power industrial equipment, military and aerospace applications, and medical devices requiring high-heat sterilization.

Manufacturing Process of Blank PCBs

The creation of a blank PCB involves specific steps. We’ll now examine the manufacturing process methodically.

Substrate Materials Preparation

The first step is preparing the substrate materials. This begins with selecting the appropriate PCB substrate material (e.g., FR-4, polyimide, or ceramic) based on the PCB’s intended application. These materials are cut to the desired size and shape using precision cutting tools.

The material surfaces then undergo thorough cleaning. This ensures proper adhesion in subsequent stages and removes contaminants that could interfere with performance.

Layer Bonding

The next step is creating the layered structure. This involves carefully arranging alternating layers of copper foil and substrate material. These layers are bonded together using heat and pressure (lamination). For multilayer PCBs, this is repeated to build up the required layers.

The heat and pressure cause the substrate’s epoxy to flow and bond the layers, creating a solid, unified structure. This bonding is crucial for structural integrity and electrical performance.

Surface Treatment

After bonding, the PCB undergoes surface treatment. This typically involves applying a photoresist coating to the copper layers. This light-sensitive material is crucial for creating circuit patterns later.

Additional finishes like tin or gold may be applied to the copper surfaces to prevent oxidation and improve solderability for component assembly.

Bohren von Löchern

Holes are crucial in PCBs. The process begins with importing drill files specifying each hole’s size and location. CNC machines drill these holes with high precision, ensuring accurate placement and consistent sizes.

Deburring removes rough edges around the holes, ensuring smooth surfaces for later plating and component insertion.

Applying Solder Mask

The solder mask layer gives many PCBs their distinctive green color. Applied over the entire surface, it exposes only areas for component soldering. This layer protects copper traces from oxidation, prevents solder bridges between solder pads, and provides electrical insulation between traces. This step is critical in preparing the blank PCB for component population.

Qualitätskontrolle

The final step is quality control. This involves tests and inspections to ensure the boards meet specifications. These may include visual inspections for physical defects, automated optical tests to verify hole placements and trace widths, and electrical tests to confirm layer integrity and the absence of short circuits. Only PCBs passing these rigorous checks are approved for use.

Applications and Uses of Blank PCBs

Blank PCBs form the basis for a vast array of electronic devices and systems. Let’s explore their varied uses.

Prototyping and Testing

A primary application of blank PCBs is in prototyping and testing new electronic designs. Blank PCBs offer engineers and designers a remarkably flexible platform for experimenting with circuit layouts and component placements. They allow for rapid design iteration, enabling quick modifications without full-scale production.

Blank PCBs are also essential for pre-etching functionality tests. This ability to test and refine designs on a blank canvas reduces development time and costs, making them a valuable asset in electronics R&D.

Custom PCB Design

Off-the-shelf solutions don’t always meet the diverse needs of the electronics world. This is where custom PCB design comes in. Blank PCBs offer unparalleled flexibility in circuit design. Engineers create bespoke layouts tailored to specific product requirements, whether a unique form factor, special performance characteristics, or integration with proprietary components.

This customization is particularly valuable for unique products or small production runs. From specialized industrial equipment to cutting-edge consumer gadgets, custom PCB designs often begin on a blank PCB.

Education and Training

In electronics education, blank PCBs are crucial. They provide students and hobbyists with hands-on learning. They offer a practical platform for understanding PCB design principles, component placement, and circuit layout. By working with blank PCBs, you can gain firsthand experience creating a functional electronic circuit, from design to assembly.

This practical approach is invaluable in bridging the gap between theory and real-world application, preparing the next generation of electronics professionals.

Massenproduktion

Beyond prototyping and custom designs, blank PCBs are also used in mass production. They serve as the standardized starting point for creating large quantities of identical circuit boards. Their consistency and reliability are ideal for automated manufacturing, where uniformity is key to efficiency and quality control.

The cost-effectiveness of using blank PCBs in large-scale manufacturing is another significant advantage, streamlining production and reducing costs without compromising quality.

PCB Repair and Rework

Even reliable electronic devices may eventually need repair or modification. Blank PCBs can effectively replace damaged sections of existing circuit boards. When a portion is damaged beyond repair, technicians can recreate the damaged section on a blank PCB, effectively extending the device’s lifespan.

Blank PCBs are also valuable for modifying existing circuits. Whether adding new functionality or updating a design, they provide a clean slate for implementing changes without replacing the entire board.

Specialized Applications

The versatility of blank PCBs extends to numerous specialized applications. In telecommunications and aerospace, high-frequency blank PCBs are crucial for the sophisticated circuits in satellite communications and radar systems. Flexible blank PCBs are ideal for wearable technology and compact electronics, enabling innovative designs for non-traditional shapes. In high-power applications and LED lighting, metal core blank PCBs provide the necessary heat dissipation for reliable performance.

From consumer electronics to industrial machinery, medical devices to military equipment, blank PCBs are the starting point for a wide range of specialized electronic applications. Their adaptability and reliability make them indispensable in the ever-evolving world of electronics.