Circuit board serial numbers might seem like just another technical detail in electronics. However, these unique identifiers are vital for tracking, managing, and understanding printed circuit boards (PCBs). Without them, maintaining quality control, managing warranties, and troubleshooting issues would be far more challenging. This guide provides a detailed look into circuit board serial numbers, explaining their importance, how to locate and interpret them, and their applications across the electronics industry.

What is a Circuit Board Serial Number

A circuit board serial number is a unique identifier assigned to a PCB during its manufacturing process. They act as a digital fingerprint for each board, containing a significant amount of information within a compact string of characters.

It must be understood that these serial numbers are not merely random combinations of letters and numbers. Notably, they may contain important details such as the board model number, flux density, test information, product batch number, and assembly quality. Basically, they encapsulate the board’s entire pedigree in a concise format.

Circuit board serial numbers primarily facilitate tracking and management of different components and parts throughout the PCB’s lifecycle. This becomes particularly important when repairs or modifications are necessary. A malfunction can be costly. It’s important to recognize that circuit board serial numbers also significantly simplify the assembly process. This level of precision is necessary. In this industry, even the slightest error can lead to significant malfunctions.

It’s clear that the benefits extend far beyond the manufacturing floor. They enable efficient tracking and management of components throughout the supply chain, facilitating inventory control and quality assurance. Apparently, these unique identifiers are demonstrably invaluable for technical support and warranty services. When a customer reports an issue, support teams can quickly reference the serial number to access relevant information about the board’s specifications and history.

It should be emphasized that serial numbers notably also ensure compatibility with necessary firmware updates. As technology advances, PCBs often require updates to maintain optimal performance or address security vulnerabilities. The serial number should allow manufacturers to identify which boards are eligible for specific updates, ensuring that the right firmware is applied to the right hardware.

Where do you find serial numbers on circuit boards

Locating serial numbers on circuit boards can sometimes feel like a treasure hunt, but with the right knowledge, it becomes a surprisingly straightforward task. Now, we will examine the various places where you might find these important identifiers.

Common Locations for Serial Numbers

Printed on stickers

Many manufacturers opt for the simplicity of printing serial numbers on adhesive labels and affixing them to the board. Stickers are typically placed in easily visible locations.

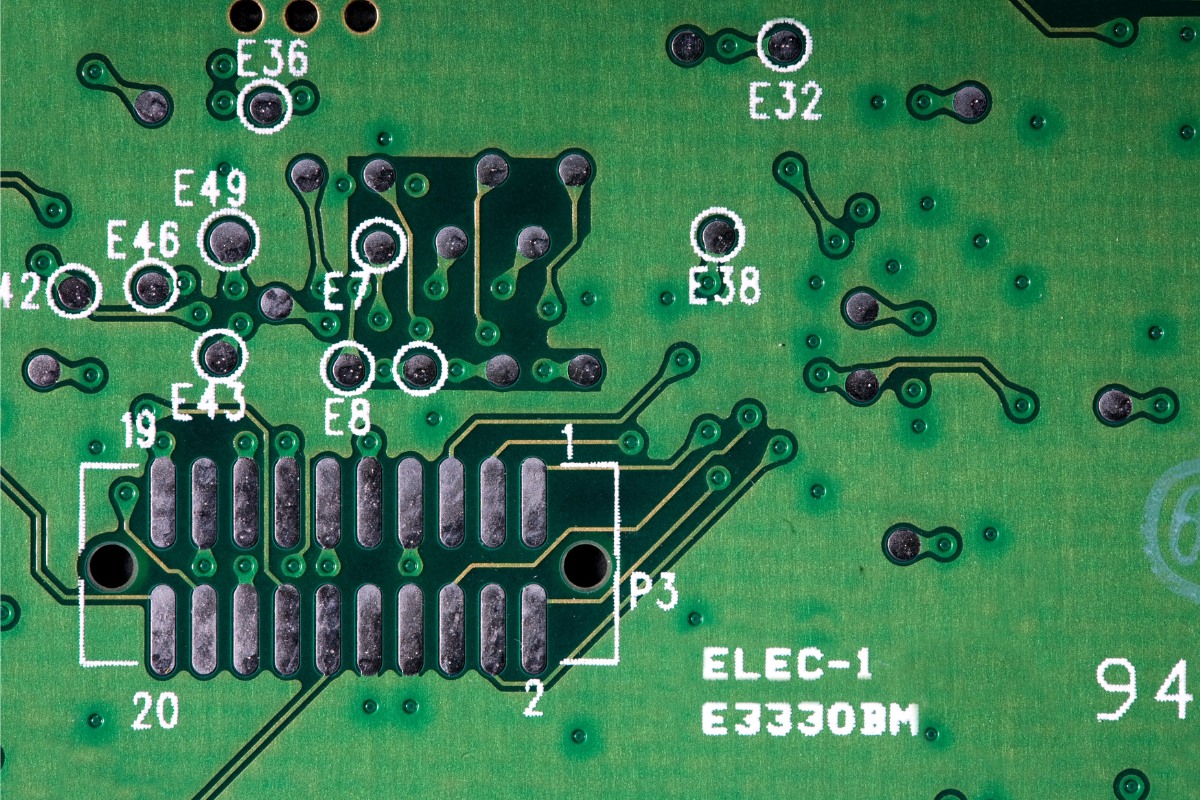

Silkscreen printing

In some cases, the serial number is printed directly onto the board’s surface using a process called silkscreening.

Etched or stamped

For added durability, some manufacturers etch or stamp the serial number directly into the bare circuit board material.

Large surface areas

When searching for a serial number, start by examining the largest surface areas of the board. Such spaces provide ample room for clear labeling.

Near identifying text

Look for areas on the board that contain other identifying information. Serial numbers are often found near text like “Serial No.” or “S/N”.

Alongside other markings

You might find the serial number grouped with other important information such as product codes, barcodes, copyright notices, or company logos.

Board edges and corners

Many manufacturers place serial numbers near the edges or in corners of the board to maximize available space for components.

Near connectors or ports

In some designs, especially those with limited space, serial numbers may be located close to connectors or ports.

Though serial numbers can be hidden or damaged, there are ways to deal with them.

Carefully move components

If the serial number is hidden beneath removable components or connectors, gently move them aside to access the label. Be careful to avoid damaging the board.

Use a flashlight

For numbers stamped or etched into the board, a flashlight can help illuminate the characters, making them easier to read.

Remove the board from its casing

In some instances, you may need to remove the board from the device’s case to access the serial number. Always follow the safety procedures when doing this.

Inspect flexible sections

Pay special attention to folded flexible and rigid-flexible PCBs, as serial numbers may be hidden in these areas.

Look for alternative identifiers

If the serial number is damaged or unreadable, look for other identifying markings such as copyright years, logos, brand names, IC part numbers, or PC board/layout codes.

Reconstruct partial labels

If only portions of the label remain, you might be able to reconstruct the serial number by first identifying the board’s manufacturing origin and date.

Other Places to Look

If you’re still having trouble locating the serial number, you can check these additional areas:

- Under large components or connector plates

- Etched onto the PCB material itself

- Printed onto flexible tail sections

- Hidden under keyboards, displays, or shields on assembled devices

Remember, manufacturers often provide documentation that can help in locating serial numbers. Consult user manuals, datasheets, or technical specifications, which may include diagrams showing the exact location of serial numbers on specific board models.

How do you decode circuit board serial numbers?

Decoding circuit board serial numbers is like solving a mystery, with each character potentially holding incredibly valuable information about the board’s origin, age, and specifications. We’ll examine the process of interpreting these cryptic strings of characters.

General Structure of Circuit Board Serial Numbers

Date code

This usually comes first, indicating when the board was manufactured.

Revision code

Immediately following the date code, you’ll often find characters indicating the board’s revision.

Manufacturer ID

Letters or numbers identifying the manufacturer or production site.

Product code

Numbers denoting the product line and model.

Check digit

A final single number or letter used for validation.

Understanding Date Codes

Date codes can be particularly tricky to decipher, as they come in various formats. Here are some common ones:

Numeric dates

- YYWW: 2-digit year, 2-digit week (e.g., 2152 for the 52nd week of 2021)

- YYYYWW: 4-digit year, 2-digit week (e.g., 202152)

Alphanumeric dates

- YYWW: 2-digit year, 1-letter month, 1-digit week (e.g., 21L3 for the 3rd week of December 2021)

- YYMM: 2-digit year, 2-digit month (e.g., 2112 for December 2021)

- YYMMDD: 2-digit year, 2-digit month, 2-digit day (e.g., 211225 for December 25, 2021)

Julian dates

Used in military and aerospace applications, representing the numeric day of the year from 1 to 366, e.g., 21359 for December 25, 2021.

Interpreting Revision Codes

Revision codes help track changes and improvements to the board design. Typically, letters A, B, and C indicate major revisions, while numbers 1, 2, and 3 are often used for minor revisions. Sometimes, lowercase letters a, b, and c are used for internal revisions.

Identifying the Manufacturer

Manufacturer IDs can take several forms, including acronyms, e.g., “QAV” for “Quality Audio Visual”, site location codes, e.g., “TPE1” for “Taipei Site 1”, or country codes, e.g., “MY” for Malaysia.

Deciphering Product Codes

Product codes often directly correspond to market model numbers or internal product codes. They can indicate the compatibility of replacement boards and are crucial when identifying boards without visual part numbers.

Verifying Check Digits

Check digits, when present, are generated through a formula using the preceding numbers. They provide a simple way to catch instances where a serial number might have been misread or misprinted.

Although it may seem complex, here’s a quick guide for beginners.

Identify the important parts

Look for groups of letters or numbers that might represent dates, revisions, or product codes.

Read from left to right

Most serial numbers are designed to be read in this direction.

Understand the meaning

Familiarize yourself with common formats for date codes, revision numbers, and manufacturer IDs.

Consult documentation

When in doubt, refer to manufacturer’s guides or industry standards for specific decoding information.

Applications of Circuit Board Serial Numbers

Circuit board serial numbers serve many purposes beyond simple identification. We will examine these applications in detail.

Troubleshooting and Repairs

Identifying known issues

Technicians can quickly determine if the board belongs to a production run with known defects or issues by referencing the serial number.

Accessing repair history

Serial numbers allow technicians to trace a board’s service and repair history, providing context for current issues and guiding repair strategies.

Selecting replacement parts

The product code within the serial number provides a positive ID for selecting the correct replacement parts or boards, guaranteeing compatibility and proper functionality.

Firmware compatibility

Knowing the board’s exact version through its serial number helps in determining compatibility with firmware updates or patches.

Warranty Claims

Proof of purchase

Serial numbers provide concrete evidence of a product’s manufacturing date, which is often used to determine warranty status.

Validation

Manufacturers can tie serial numbers to original sale records, validating the date and location of purchase for warranty purposes.

Fraud prevention

Serial numbers help combat fraudulent warranty claims on fake boards or devices by providing a unique identifier that can be verified against manufacturer records.

Inventory Management

Detailed tracking

Tracking boards by serial number allows for detailed inventory status and life cycle monitoring, from production to end-of-life.

Revision grouping

Revision codes within serial numbers help group boards by design iterations, guaranteeing compatibility when managing inventory for repairs or replacements.

Stock optimization

Production dates derived from serial numbers help determine the aging of stock, allowing companies to optimize turnover and manage product lifetimes effectively.

Supply chain visibility

Serial numbers facilitate easy connection between supply chain and manufacturing visibility, improving logistics management.

Identifying Counterfeits

Authenticity verification

Genuine serial numbers can be verified against manufacturer databases, quickly identifying potential counterfeits.

Pattern recognition

Counterfeit boards often have nonsensical, invalid, or duplicated serial numbers that can be spotted upon close inspection.

Check digit validation

Verifying check digits provides a simple yet effective test for identifying counterfeits, as fake serial numbers often fail this mathematical validation.

Component verification

Technicians can identify discrepancies that might indicate a counterfeit product by comparing board internals against manufacturer parts lists for a specific model number derived from the serial number.

Using Barcodes for PCB Serialization

Because the complexity and volume of PCBs in production increase, manufacturers are turning to more sophisticated methods of serialization. One method that has gained popularity is the use of barcodes. We will examine how barcodes are changing PCB serialization and what’s involved in their implementation.

Overview of Barcode Serialization for PCBs

Barcodes have become a common sight on PCBs, serving as a machine-readable representation of the board’s serial number. These barcodes can store a variety of information, including:

- Manufacturing date and location

- Flux density

- Solder temperature

- Component numbers

- Test data

The advancement of barcode technology has led to more sophisticated systems capable of storing larger amounts of data in smaller spaces, making them particularly suitable for the limited space on PCBs.

Advantages of Using Barcodes

Machine readability

Barcodes provide a quick and accurate method for machines to read serial numbers, speeding up processes like inventory management and quality control.

Data density

Modern barcode formats can encode a large amount of data in a relatively small space, which is important for PCBs where space is limited.

Durability

Barcodes can be printed, stamped, or laser-etched directly onto the board surface, guaranteeing longevity and resistance to wear.

Versatility

Modern barcode readers can reliably identify both 1D and 2D barcodes, offering flexibility in implementation.

Cost-effectiveness

Barcode systems are usually less expensive to implement than more advanced technologies like RFID.

Disadvantages of Using Barcodes

Line of sight requirement

Barcodes require a direct line of sight between the label and the reader, which can be challenging in some PCB configurations.

Space limitations

High-density boards may lack sufficient space for a single barcode, potentially requiring multiple barcodes that can be difficult for a single reader to process.

Environmental factors

Dirt, damage, or wear can make barcodes unreadable, potentially leading to issues in long-term traceability.

Data capacity limitations

Although 2D barcodes can store more data than 1D barcodes, they still have limitations compared to more advanced technologies like RFID.

Different Barcode Formats

1D Barcodes

- Code 39: An older, widely supported format suitable for alphanumeric data.

- Code 128: A more compact format that can encode all 128 ASCII characters.

2D Barcodes

- DataMatrix: A square or rectangular format that can store a large amount of data in a small space.

- PDF417: A stacked linear format that can encode up to 1800 characters.

- QR Code: A square format popular in consumer applications because of its readability by smartphones.

Choosing the Right Barcode Format

Data volume

If you only need to encode a simple alphanumeric string of less than 20 characters, you can use Code 128, which is often sufficient and widely compatible.

Space constraints

For PCBs with limited space, 2D formats like DataMatrix can encode more information in a smaller area.

Industry standards

Some industries have specific requirements or preferences for particular barcode formats.

Reader compatibility

You should make sure your chosen format is compatible with the barcode readers in your production and supply chain.

Consumer interaction

If the PCB is in a consumer product where end-users might need to scan the code, QR codes are widely supported by smartphone cameras.

RFID Technology for PCB Identification

Radio-Frequency Identification (RFID) technology has become a powerful tool for PCB identification and serialization, offering several advantages over traditional methods. This section will examine how RFID is being used in the PCB industry and its advantages.

Overview of RFID Technology for PCB Identification

RFID technology uses electromagnetic fields to automatically identify and track tags attached to objects. In the context of PCBs, RFID chips are embedded or attached to the board, holding crucial manufacturing and product information. This may include:

- Board serial number

- Model number

- Manufacturing processes involved

- Individual product information

One important feature of RFID technology is that it allows for secure access and updating of information at any point during the manufacturing, shipping, or repair processes. This adaptable nature of RFID makes it particularly valuable in the constantly changing field of electronics manufacturing.

Advantages of Using RFID for PCB Identification

Real-time visibility

RFID provides an off-the-shelf solution for automated real-time visibility of the board throughout its lifecycle.

Comprehensive tracking

The technology maintains a complete electronic pedigree for tracking and traceability of parts or work-in-progress.

Enhanced management

RFID systems often come with real-time dashboards, various alerts, and reports for management on the shop floor, improving operational efficiency.

Automatic traceability

RFID enables automatic traceability of work-in-progress, reducing manual errors and improving productivity.

Proactive issue management

Real-time alerts allow for anticipating and addressing production issues before they escalate.

Improved planning

RFID data can be used for ready assessment of delivery capabilities for new orders, improving production planning.

Quality control

The technology allows for quick isolation of defective components, improving quality management.

Authentication

RFID provides integrated product authenticity, which is important in industries where counterfeit components are a concern.

Supply chain efficiency

RFID facilitates quick reconciliation between shipping and receiving, and easy connection between supply chain and manufacturing visibility.

Flexibility

RFID chips can be easily installed on the surface of the PCB, allowing for data updates during various stages of the product lifecycle.

Implementing RFID on PCBs

Chip mounting

RFID tags or chips can be mounted onto the PCB as a standard SMT component, integrating with existing manufacturing processes.

Non-contact programming

A physical connection to the RFID chip is not needed for programming it with the manufacturing pedigree information, which can streamline the production process.

Rapid data access

Important data can be accessed quickly from the chip without a physical connection, improving efficiency in various stages of the product lifecycle.

Environmental considerations

When implementing RFID, the operating environment of the PCB should be taken into account. Factors such as temperature, humidity, and electromagnetic interference can affect RFID performance.

Security measures

Because RFID allows for remote reading, implementing proper security measures to protect sensitive data is essential.

Integration with existing systems

RFID systems should be integrated with existing inventory management, quality control, and supply chain systems for maximum benefit.

Special Considerations for Circuit Board Serial Numbers

Although the basic principles of circuit board serial numbers are widely applicable, some situations require special attention. We will examine some of these scenarios and how they impact the use and interpretation of serial numbers.

Proprietary Numbering Systems

Lack of inherent information

Unlike standard serial numbers, proprietary schemes may not have inherent date or revision data that can be easily interpreted without reference materials.

Decoding challenges

Interpreting these numbers often requires access to proprietary guides or databases, which may not be publicly available.

Security implications

For classified or restricted boards, special access or security clearance may be required to obtain decoding documentation.

Standardization issues

Proprietary systems can create challenges when boards need to interface with components or systems from other manufacturers or industries.

Serial Numbers for Compliance

Format requirements

Compliance-driven serial numbers may need to follow strict formats dictated by regulatory bodies.

Minimum height standards

Some regulations specify minimum heights for serial number characters to guarantee readability.

Mandatory data fields

Some industries require specific data to be encoded within the serial number, such as manufacturing date or lot number.

Multiple labels

To meet different standards, boards may need to feature multiple serial labels, each conforming to a different regulatory requirement.

Traceability requirements

Some industries mandate complete traceability of components, requiring more comprehensive serialization systems.

Serialization After Manufacturing

System integration serialization

Some assemblies and multi-board products are serialized at the time of system integration rather than individual board manufacturing.

Traceability challenges

When top-level product serials are assigned after integration, a system that can trace these serials back to the underlying board identifiers must be maintained.

Field servicing considerations

Component labels may be added post-production for field servicing purposes. Additional identifiers need to be managed in conjunction with original serial numbers.

Retrofitting serialization

In some cases, older boards or systems may need to be retrofitted with modern serialization methods, requiring careful planning to maintain consistency with existing records.

Handling Serial Numbers in Rework and Repair

Maintaining original serials

Maintaining the original serial number even after rework is usually necessary to preserve traceability.

Documenting changes

Any modifications made during rework should be documented and associated with the original serial number.

Secondary serialization

In some cases, repaired boards may receive a secondary serial number to indicate their repaired status while maintaining the original identifier.

International Considerations

Language and character set issues

Serial numbers should ideally use characters that are easily recognizable across different languages and writing systems.

Country-specific requirements

Some countries may have specific requirements for product serialization, which need to be accommodated in global manufacturing and distribution processes.

Customs and import/export considerations

Serial numbers may play a role in customs documentation and import/export processes, requiring careful management in international supply chains.