Blog

-

The High Cost of “Indestructible”: A Guide to Repairable Ruggedization

Ruggedizing industrial electronics by fully potting printed circuit boards can lead to expensive repairs or total replacement. Selective mechanical reinforcement like staking heavy components and corner bonding BGAs preserves serviceability, reducing lifecycle costs and improving repairability without sacrificing protection.

-

The Floor Drops Out: Why Your PCB Laminate is Failing Drop Tests (And Why It’s Not a Material Defect)

Bester explains why PCB laminates crater under drop tests, showing that pad cratering is a mechanical failure, not a resin defect. The article links mounting stiffness, teardrops, and solder choice to energy absorption and board resilience.

-

The Invisible Failure: When Selective Soldering Eats Its Own Connection

Cold, hidden failures in selective soldering threaten high-rel boards long after joints look perfect. This piece explains copper dissolution under a shiny fillet and why temperature, flow, and copper content drive a dangerous, unseen erosion.

-

The Thermal Lie: Why Your Void Criteria Are Failing Your Hardware

Voiding percentages aren’t a reliable gauge of a part’s reliability. Heat flow and void location trump total voids, and true reliability comes from measuring dynamic thermal response (Zth) and junction temperature, not chasing a perfect X-ray image.

-

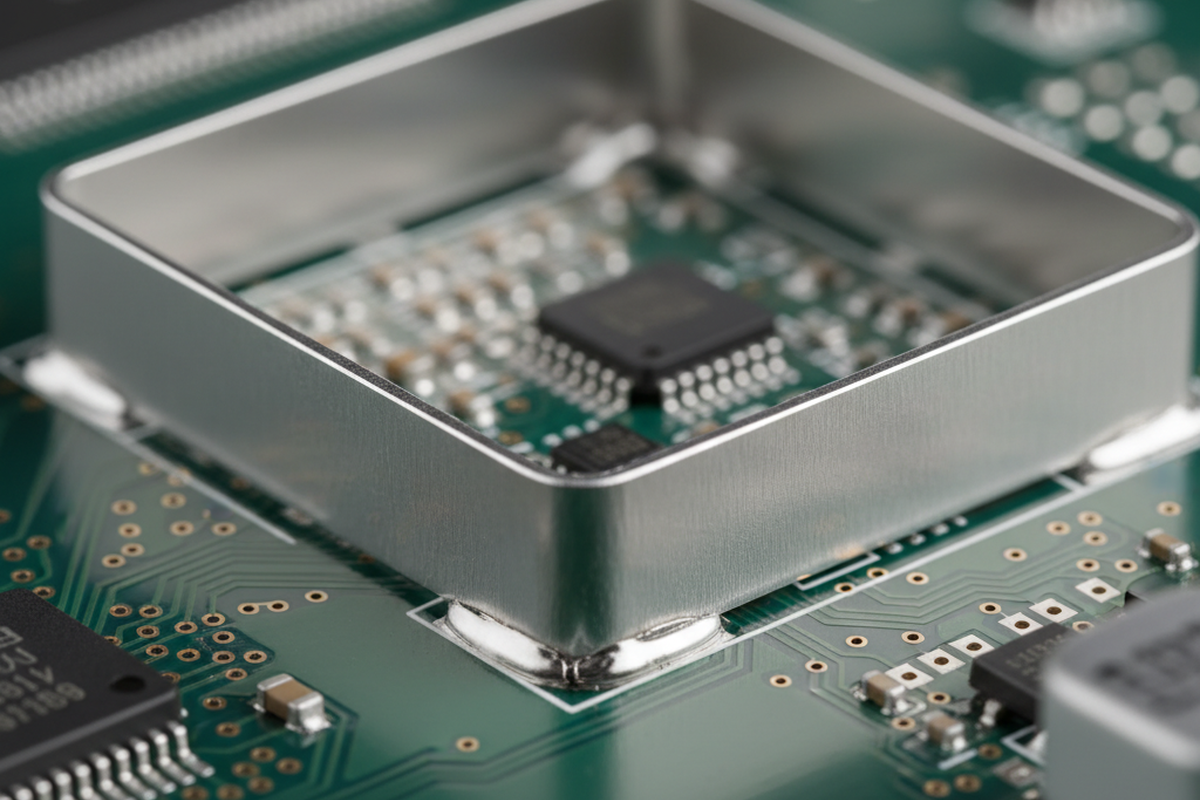

The Physics of the Shield: Avoiding the “Bead Trap” in RF Assembly

RF shield bead be careful: the shield can on a mixed-signal board is a silent yield killer. This guide shows how to prevent it with dash patterns, reduced paste, and two‑piece shields or clips for easy inspection and reliable reflow.

-

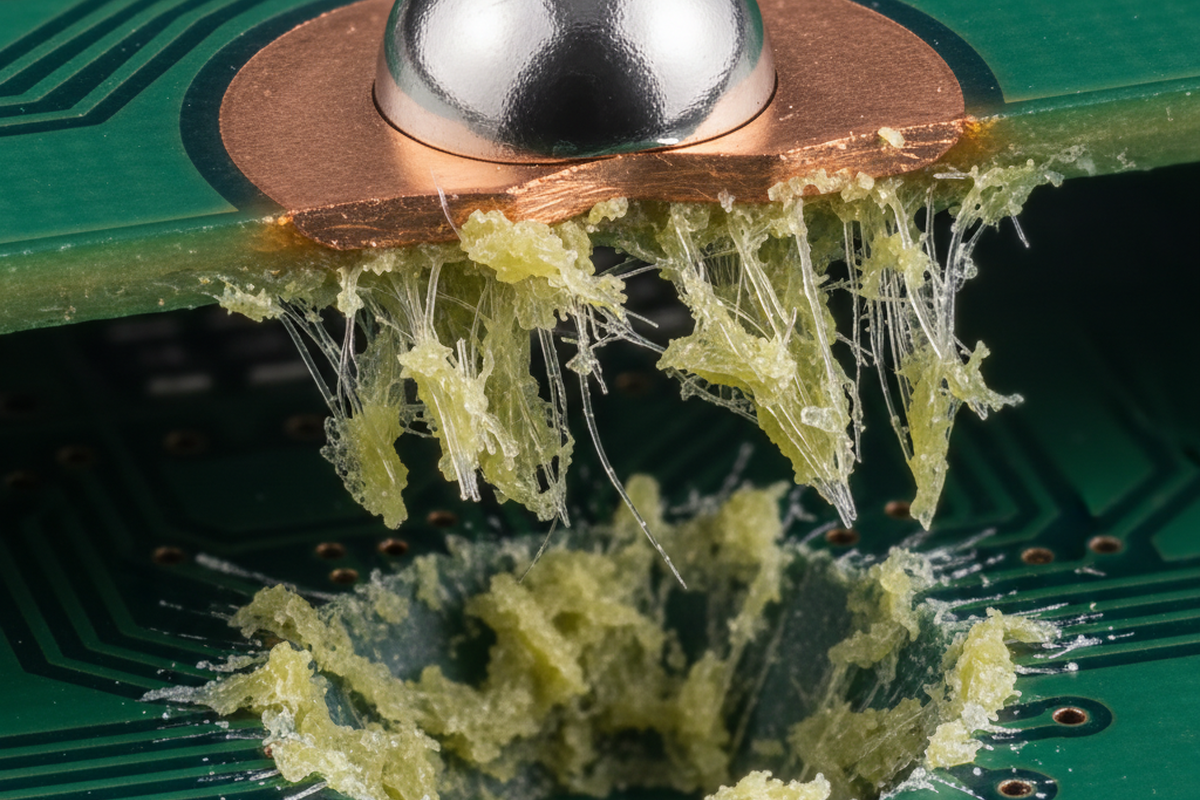

The Thermodynamics of Failure: Why Potting Cooks Your Boards

Potting electronics isn’t a simple drying process; it’s a violent exothermic reaction. The internal heat generated by curing epoxy can easily exceed 180°C, cooking sensitive components and causing failures from thermal shock and CTE mismatch long before the device reaches the field.